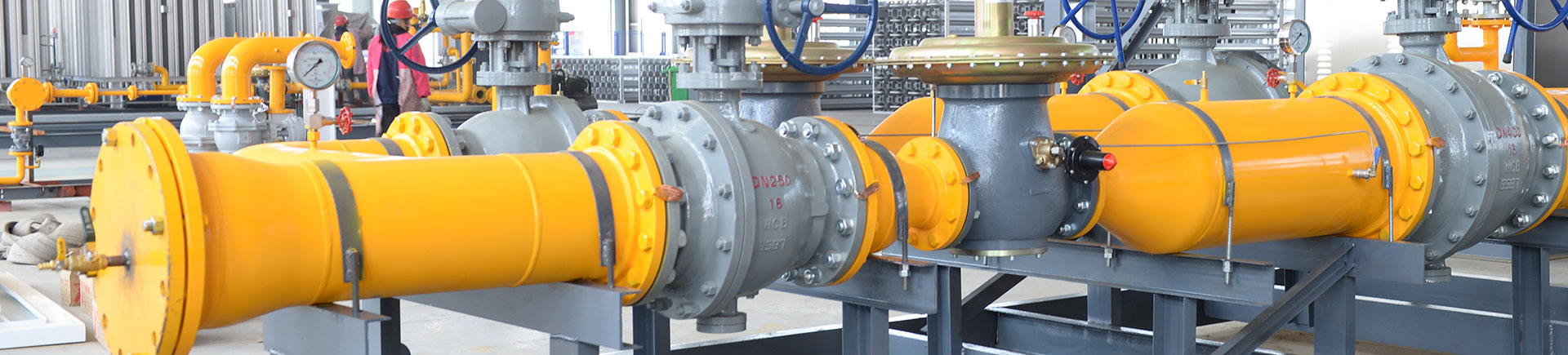

Classification: CNG Pressure Reduction Skid

Release time: 03-30-2024

Number of views: 62

Product details

As China’s energy structure evolves and environmental protection efforts intensify, the development and utilization of natural gas have rapidly advanced. Compressed natural gas (CNG) involves purifying and compressing wellhead or pipeline natural gas for high-pressure storage and transportation, delivered to usage sites where it is depressurized through multi-stage heat exchange before being directly input into the supply network for various users.

Economic Scope and Supply Capacity:

The CNG pressure reduction station is economically viable within 300 kilometers, generally not exceeding 500 kilometers, suitable for supplying 2000-4000 households with a gas supply volume of 200-5000 Nm³/h. Too large or too small a volume increases the unit cost of gas consumption.

This system involves smaller investment scales and shorter construction periods compared to long transmission pipelines, providing quick capital recovery. It can also serve as a peaking and backup gas source for long transmission pipelines in the future.

Process Overview:

The working principle of a compressed natural gas pressure reduction station involves high-pressure natural gas from skid-mounted tanks being preheated, progressively depressurized, and undergoing safety control, metering, odorization, and other processes to achieve pressure levels that meet regulatory standards for pipeline transmission. Pressure adjustment can be implemented as two-stage or three-stage regulation.

Structural Overview:

The compressed natural gas pressure reduction station is divided into the following functional sections based on the layout and functions of the equipment:

Unloading System:

High-pressure hoses, quick-connect couplings, high-pressure valves.

Pressure Regulation and Heat Exchange System: High-pressure emergency cutoff valves, heat exchangers, regulators, vent valves.

Flow Metering System: Flow meters.

Control System: Central control console.

Heating System: Gas boilers, hot water pumps, etc.

The high-pressure natural gas from the skid-mounted tanks first enters the pressure regulation and heat exchange system through the unloading system. Inside, it undergoes two heat exchanges and two or three pressure reductions before entering the flow metering and odorization system, and finally into the distribution network. The heating system provides the necessary heat for the gas pressure reduction process, while the control system monitors the entire system.

Pressure Regulation Process:

Two-stage Regulation Process: Initially, high-pressure hoses and quick-connect couplings connect to the skid-mounted tankers. Compressed natural gas passes through ball valves and high-pressure cutoff valves into a primary heat exchanger where the gas is heated, then through a primary regulator to reduce pressure to 1.0-4.0 MPa, followed by secondary heat exchange and regulation down to 0.1-0.4 MPa, metered for flow, and finally odorized before entering the medium-pressure network. All stages of gas pressure, temperature, flow, water temperature, critical valve controls, and switching between paths are interlock controlled by the central console.

Three-stage Regulation Process: Similar to the two-stage process, with an additional third stage of pressure reduction to further fine-tune the outlet pressure suitable for the medium-pressure network.

This comprehensive setup ensures efficient, safe, and environmentally friendly distribution of natural gas to various consumers.

- Previous:

- Next: CNG Pressure Reduction Skid