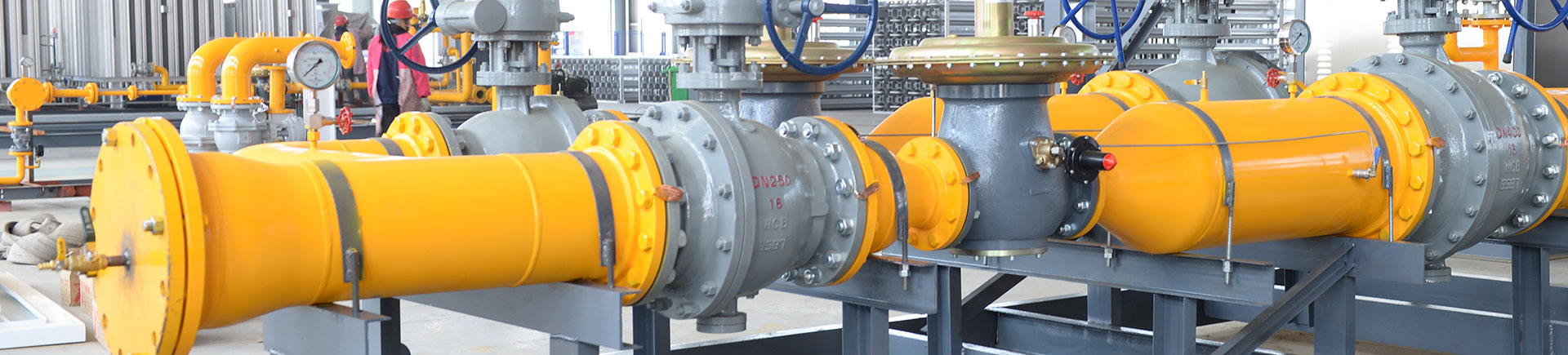

Classification: LNG Vaporization Station (Skid)

Release time: 03-30-2024

Number of views: 48

Product details

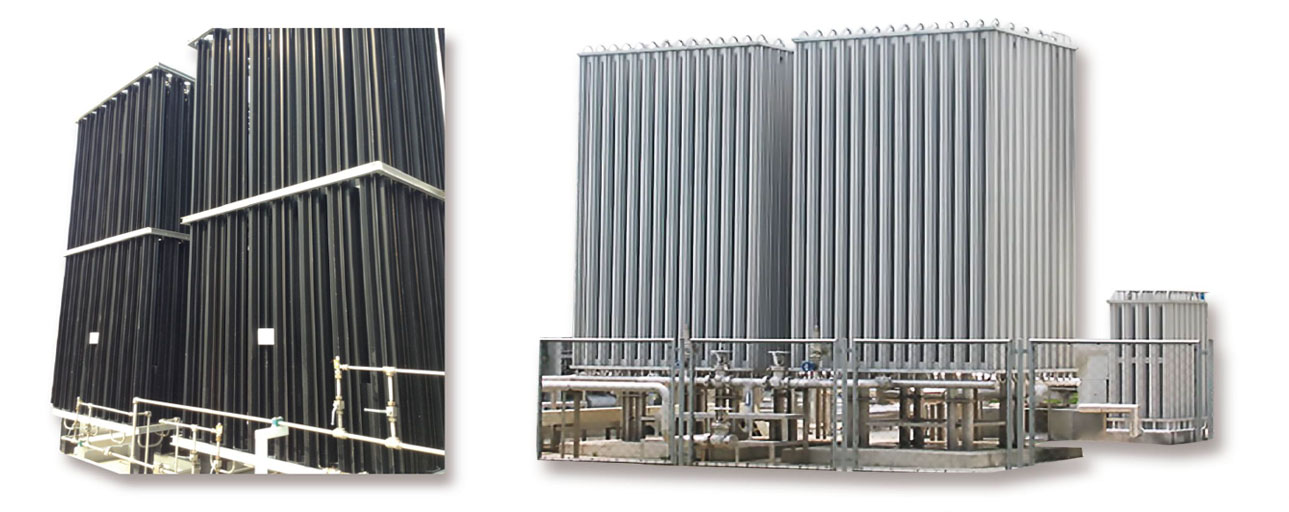

The ambient air vaporizer uses the natural convection of air to heat the exchange tubes containing low-temperature liquid, fully vaporizing it into gas. It is an efficient and energy-saving heat exchange equipment that integrates ambient air and heating vaporization functions, serving as an alternative to heated vaporization products.

Structural Features:

No energy consumption, no pollution, environmentally friendly;

Easy installation and maintenance;

Specialized aluminum material for heat exchange, efficient, lightweight design with a long service life;

Special oversized diameter aluminum heat exchange tubes for rapid defrosting, effective internal fin structure significantly enhances the heat exchange;

Aesthetic 'bridge' connection design, eliminating thermal expansion and contraction stress during operation;

Special anti-oxidation treatment on the surface of the heat exchange tubes;

Optimized process design reduces pressure drop to a minimum, prevents any streaming issues, ensuring flow rate remains within safe limits;

Ample design margin;

Advanced high-pressure tube composite technology ensures full contact between the pressure tube and the heat exchange tube, guaranteeing efficient heat transfer;

Can be designed and manufactured to electronic grade standards.

Product Specifications:

Applicable Mediums: Liquid natural gas (LNG), liquefied petroleum gas (LPG), liquid oxygen (LOX), liquid nitrogen (LIN), liquid argon (LAR), liquid carbon dioxide (LCO2), ethylene (LC2H4), etc.

Flow Rate per Unit: 10-10,000 Nm³/h;

For higher flow rates and longer continuous full-load operation, multiple units can be used in parallel or in a switching configuration;

Design Conditions: Temperature -10°C, relative humidity 70%, continuous vaporization capacity for 8-12 hours.

- Previous: LNG mobiles Vaporization Skid

- Next: LNG Skid-mounted Filling Station